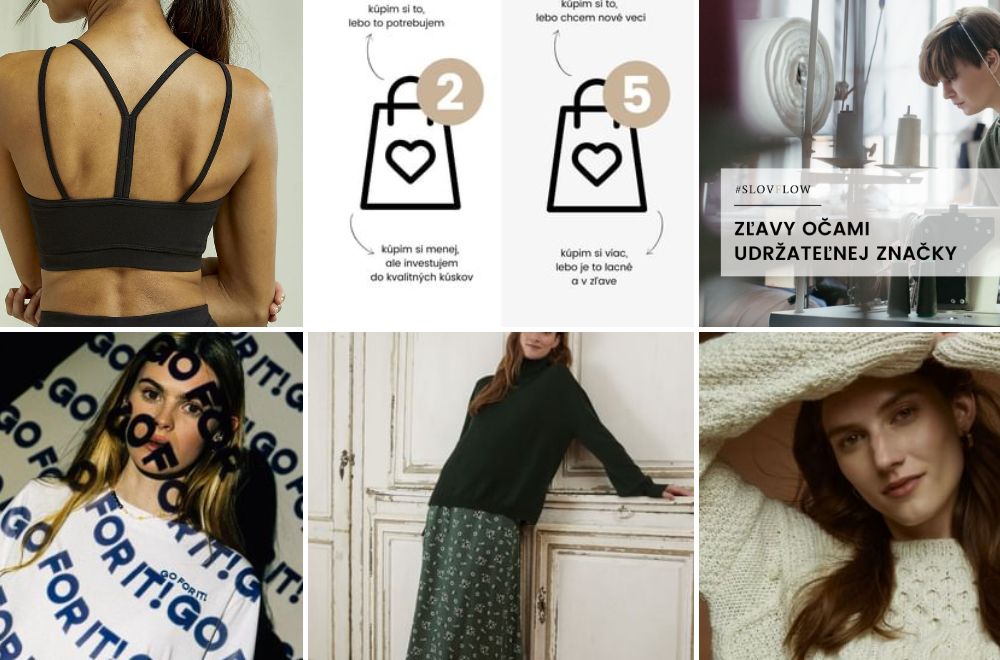

Zľavy očami udržateľnej značky: Potrebujeme, aby si ľudia uvedomili skutočnú hodnotu produktov

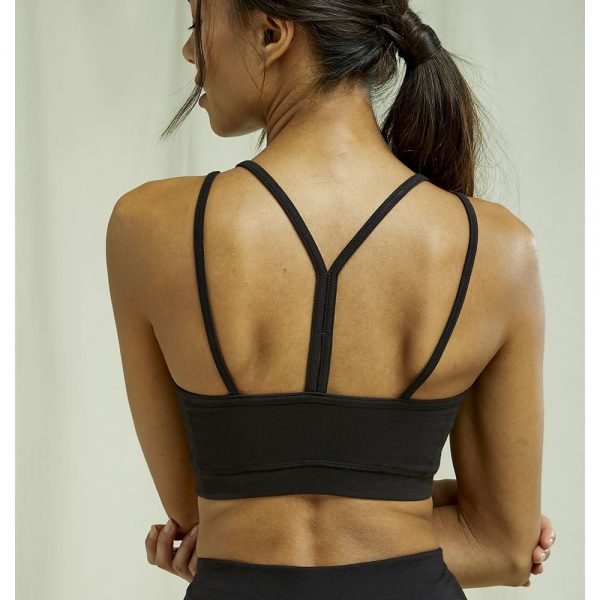

Aký je názor udržateľných značiek na zľavy a ako masívne výpredaje iných značiek ovplyvňujú ich podnikanie. Prečítajte si rozhovor so Sussesbag a WAKIVAKY.